When you run a small business, managing your supply chain feels overwhelming. You’ve got vendor contracts in one folder, inventory levels in a spreadsheet and delivery dates scattered in your emails.

A customer relationship management (CRM) system for supply chain management puts all this data in one place. You see your entire supply chain from a single dashboard.

In this guide, you’ll learn how CRMs help small and medium-sized businesses manage their supply chains. You’ll find the essential features to look for and see how Pipedrive keeps your operational efficiency on point.

What is CRM in supply chain management (SCM)?

Customer data is a powerful tool for supply chain management. Your CRM already tracks which products customers want, when they buy and how much they typically order.

With this data, you can figure out what to stock, when to reorder and which suppliers matter most to your business.

Here’s how your CRM software helps create a more customer-centric supply chain:

Use sales data to predict inventory needs. Your CRM collects valuable information about past purchases, customer preferences and sales trends. If you sold 200 units last quarter, you’ll probably need to stock similar levels next quarter.

Connect your sales pipeline to purchasing. CRMs generate sales forecasts that can guide inventory sales planning. When you link your forecasts with inventory management, you can stock the right products and prevent overstocking and stockouts.

Track which products your customers want. Understanding customer demand means you can tell suppliers what you’ll need. Because you both see what is coming, you can negotiate better deals and build stronger customer relations.

You can use a traditional CRM to gather data and improve supply chain operations. Some CRMs go even further, integrating with your supply chain software to keep everything together.

Traditional CRM vs. supply chain CRM

Here’s a comparison of how a traditional small business CRM supports your supply chain versus a CRM that integrates with other software:

Type | How it supports your supply chain |

Traditional CRM | Export your sales data and manually update your inventory system. Check customer demand in your CRM, then switch to a separate tool to place supplier orders. |

Integrated supply chain CRM | Everything connects automatically. When a customer places a large order, your system checks current stock levels and triggers reorder alerts if inventory runs low. |

Traditional CRM focuses on lead generation, sales and marketing campaigns. A supply chain-integrated CRM uses the same data for purchasing, production and inventory. It gives you both CRM and supply chain management in one logistics system.

Pipedrive falls between these approaches. It’s a sales CRM that excels at tracking customer relationships and sales data and integrates with popular inventory management and e-commerce platforms.

You get the insights you need to improve your supply chain and you can connect with specialized tools to manage operations.

4 key benefits of using CRM for supply chain management

Small businesses struggle with SCM because their information lives on different platforms. A supply chain CRM system brings everything together, giving you a competitive advantage and improving profitability through:

Better supplier relationships. Your CRM tracks every supplier. You see which ones always deliver on time and which ones cause problems. Then, you can build relationships with the good ones and find backups for when things go wrong.

Smarter inventory planning. Instead of guessing what to order, you can see which products sell best and predict your needs. Better inventory planning means less cash tied up in slow-moving stock, which is critical when managing tight cash flows.

Faster customer service. With everything in one system, you can answer inquiries quickly. If someone asks about an order, you can check stock, see delivery dates and give them accurate information immediately. Better service improves customer retention.

Reduced costs and admin work. Automated processes do time-consuming work for you. Your CRM reminds you about supplier contracts that need renewing and creates sales reports instantly. You get more time to sell and grow your business.

Lowlander Beer is a powerful business success story using CRM. Because its sales data was not organized, the company had difficulty predicting demand and managing inventory.

To solve this, they moved everything into Pipedrive and cut the time to close sales by 75%. They even use Pipedrive to track point-of-sale materials like fridges and coasters per account, aligning marketing efforts with their overall supply chain.

These benefits sound great in theory, but you need the right tools to make them happen. The good news is you don’t need enterprise software to start.

8 essential features for a CRM for supply chain management

When choosing a CRM platform to help with your supply chain, look for these functions:

Supply chain CRM feature | What it is and why it matters |

This feature stores suppliers and key contacts in an accessible place, so you always know who to reach out to | |

2. Communication tracking | A CRM logs every email, sales call and meeting with your suppliers so you can maintain strong relationships |

Custom fields let you add specific data unique to your supply chain, beyond standard CRM fields | |

4. Reporting and analytics | Robust reporting tools mean you pull insights from your sales and customer interactions to forecast demand in real-time |

Automation streamlines repetitive tasks to save you time and prevent mistakes from manual data entry | |

6. Integration capabilities | A strong CRM syncs with other essential business software to avoid data silos and save you even more time |

7. Activity management | Activity management lets you schedule and track supply chain-related tasks, preventing them from slipping through the cracks |

8. Document management | Storing documents within your CRM means you can attach contracts and product specifications to the relevant records |

These eight features will ensure your CRM can handle most SCM tasks. In the next section, you’ll learn how to use Pipedrive as an intuitive small business SCM system.

Download five free sales order templates

How to use Pipedrive’s CRM for supply chain management

Pipedrive’s CRM is a valuable tool for small businesses looking to manage their supply chain effectively.

Here’s how to set up Pipedrive as a supply chain command center.

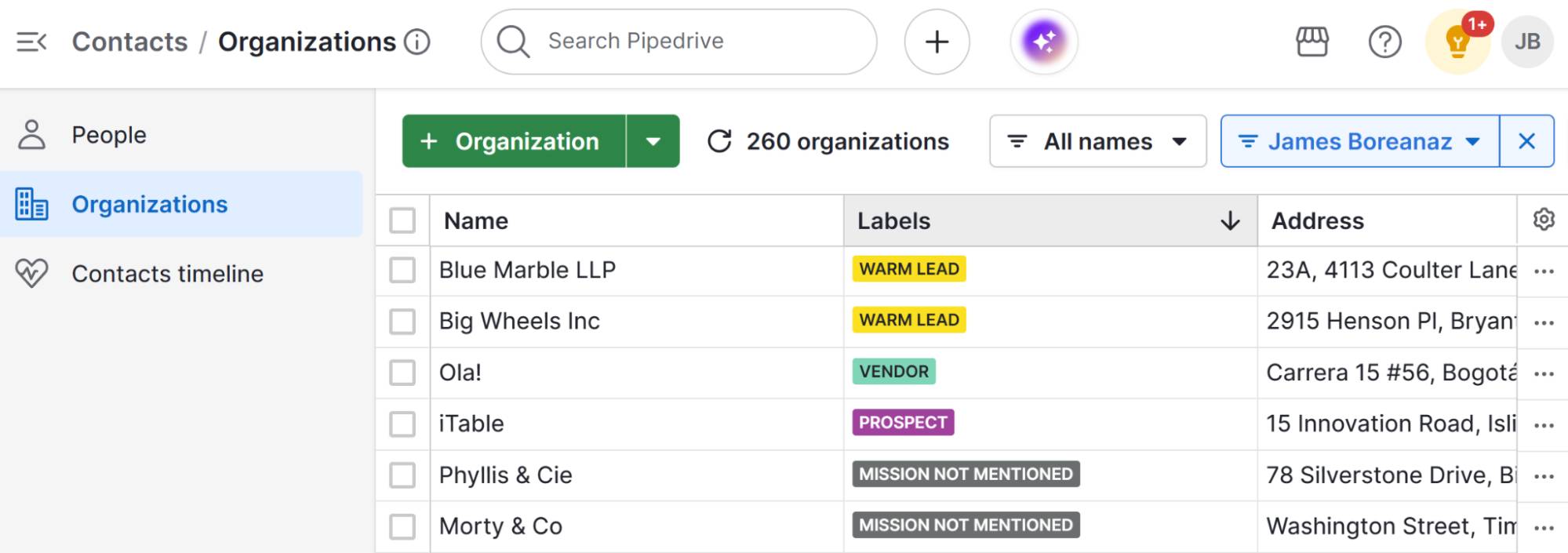

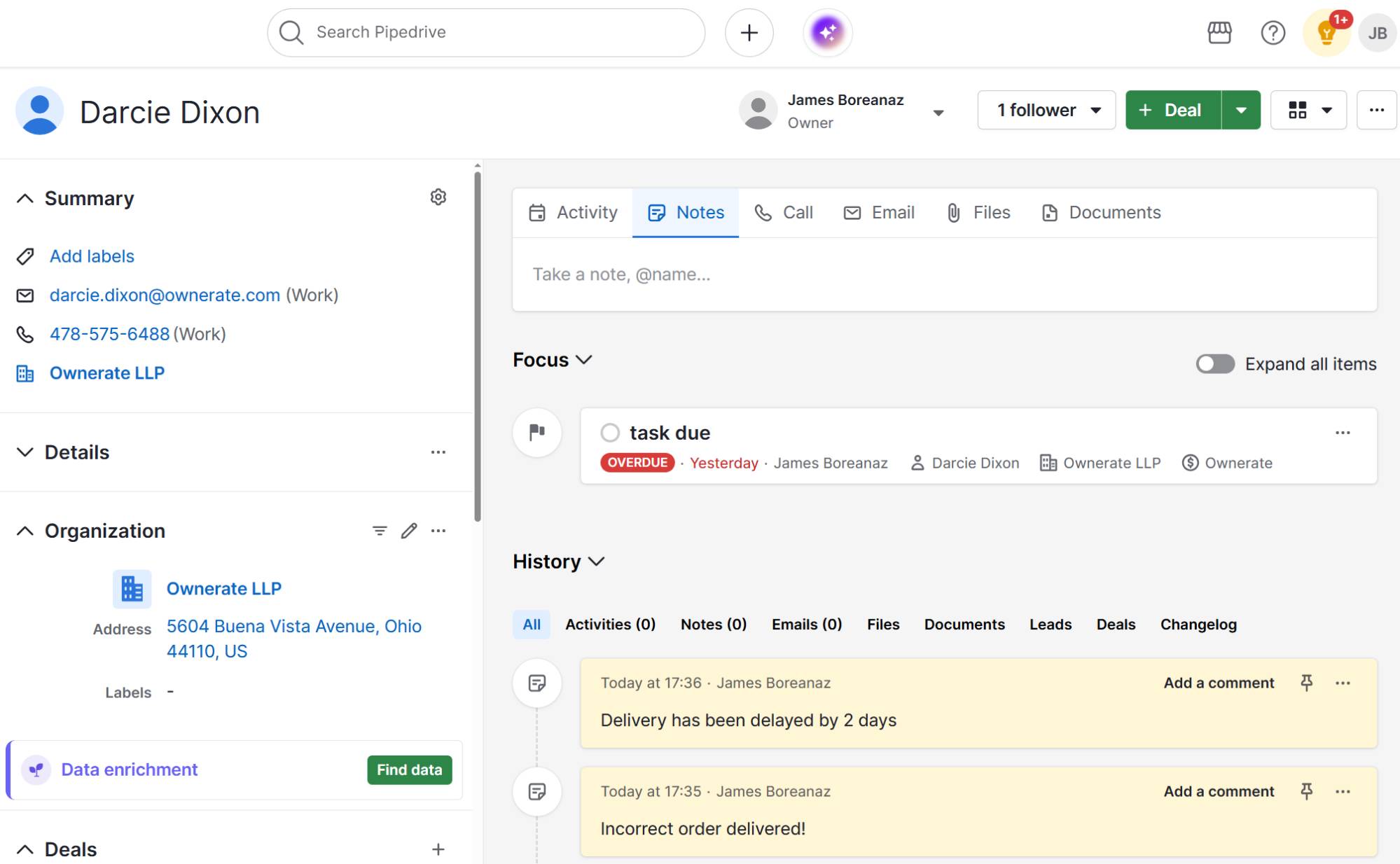

1. Track supplier contact information and communication history

Keeping accurate supplier records helps your small business run smoothly. Pipedrive centralizes key supplier information so your supply chain is clear and easy to manage.

Start by creating an organization record for each supplier company you work with. Think of this like a digital profile for each vendor. Add these by pressing the “+ Organization” button from the list view of your people tab.

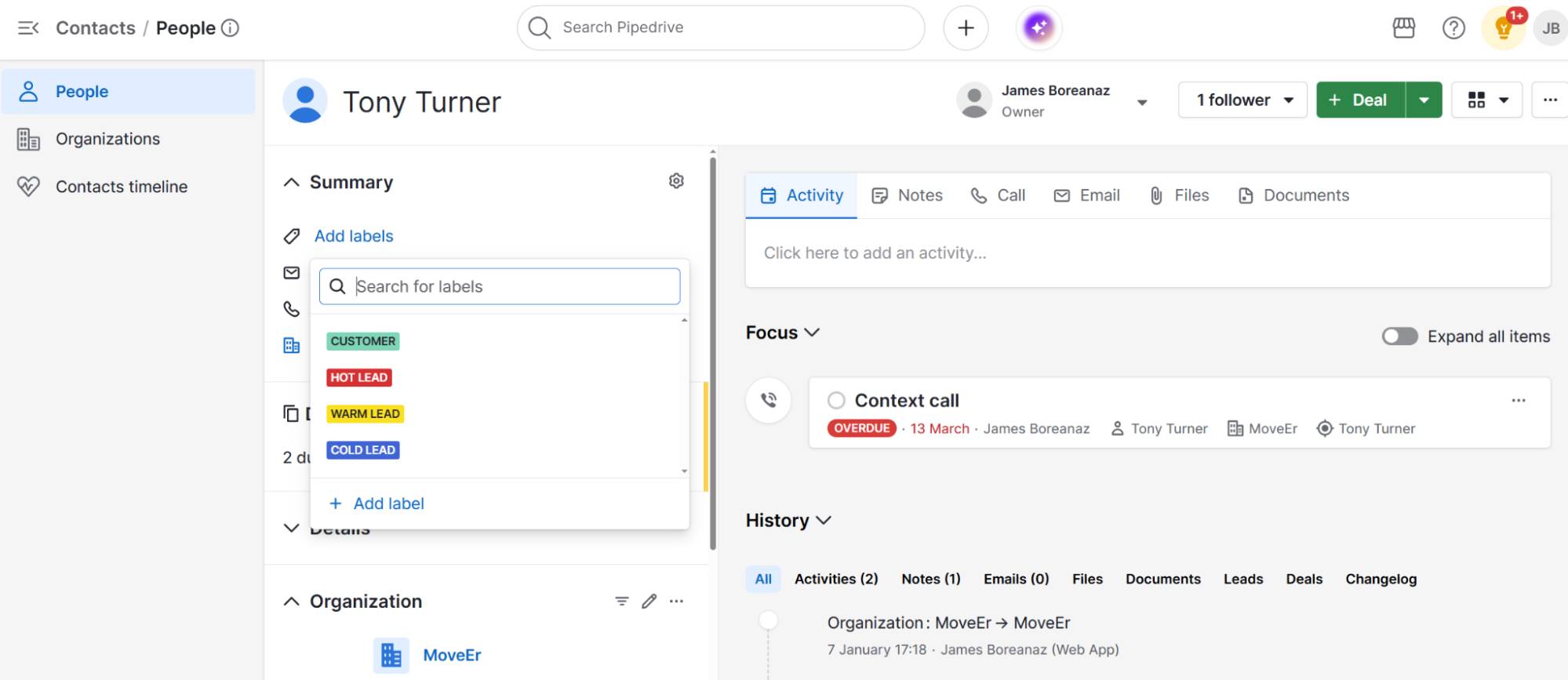

Add “Person” records for your primary contacts, like their sales representative or account manager, inside each supplier’s record. This way, your team always knows exactly who to reach out to.

Your communication history with suppliers and distributors is as essential as their contact details. Every time you communicate with a supplier, log it in their Pipedrive record (even if it’s just a LinkedIn message).

You’ll build a complete history of your conversations over time. Suppose you must recall a specific detail about a past order or a negotiation. In that case, you can quickly find it in the supplier’s profile.

Note: Pipedrive’s Smart Docs feature lets you create and store sales documents in your CRM. Use it to create quotes quickly, get e-signatures on contracts and centralize essential documents for easy access.

2. Set up deal stages that reflect your order fulfillment process

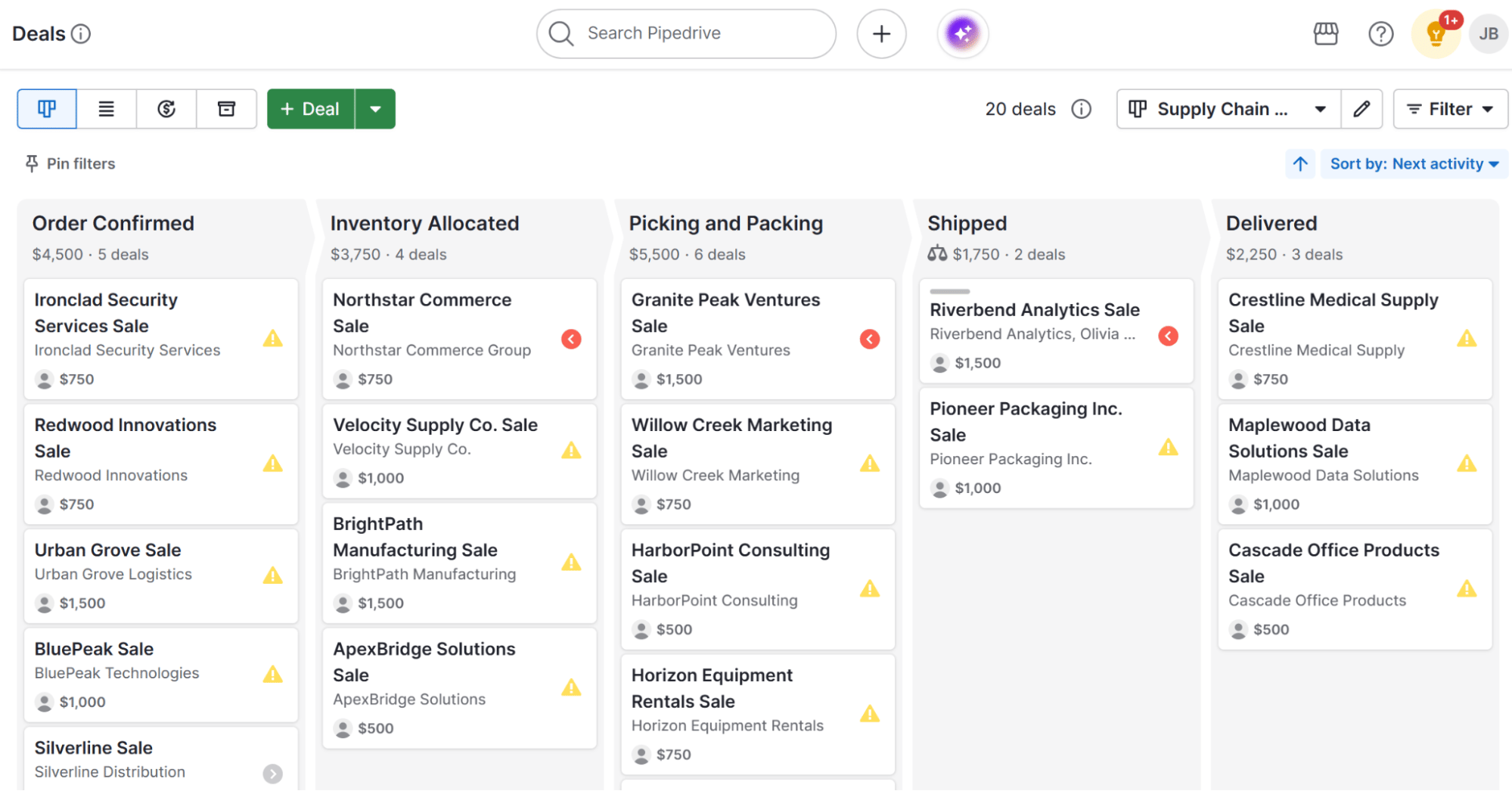

Pipedrive’s visual pipelines are a powerful tool for tracking sales processes. You can extend this power beyond sales by creating a new pipeline that mirrors your product’s journey from a closed sale to delivery.

Start by creating a new pipeline in Pipedrive, separate from your main sales one. Name it something like “Order fulfillment” or “Product delivery”.

Create a series of deal stages within this new pipeline for each step your product takes after a customer buys it. Think about the actual physical or digital journey your product makes.

Your stages could look something like this:

Order Confirmed: the sale is final and the order details are ready

Inventory Allocated: you have confirmed the product’s availability from your stock

Picking and Packing: your team is gathering the items and preparing them for shipment

Shipped: the product has left your product warehouse or supplier and is on its way

Delivered: the customer has received their order

Drag and drop each deal (now representing a customer order) from one stage to the next as it progresses.

Every stakeholder will see where each order stands. They quickly spot bottlenecks and give customers accurate delivery updates when they ask.

Note: Don’t overlook supply risk management. Small businesses are vulnerable to supplier disruptions. Use your CRM to track backup suppliers for critical items. The goal is to spot issues before they affect business continuity.

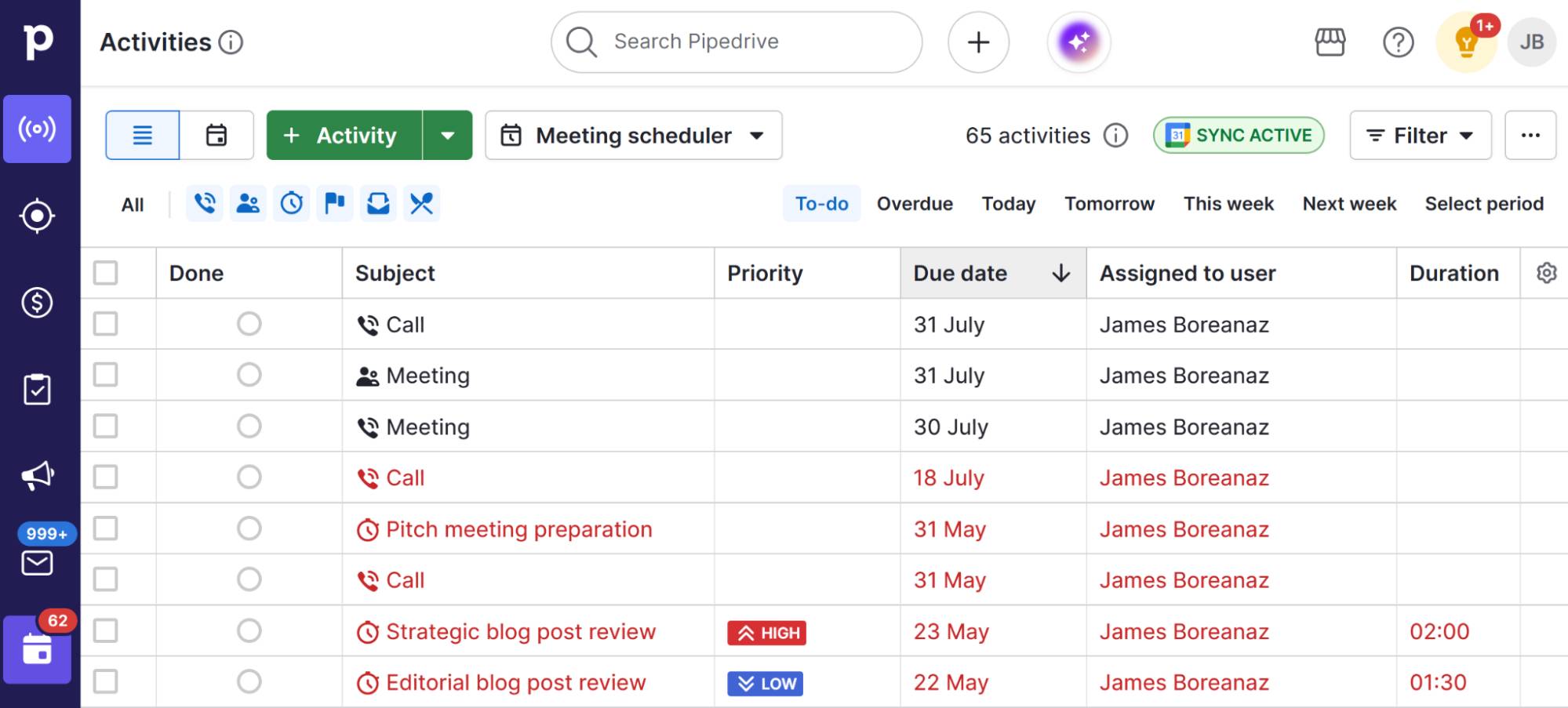

3. Monitor supplier performance and delivery schedules

Knowing which suppliers consistently deliver on time is essential. Late deliveries upset your customers and damage your business’s reputation.

Pipedrive helps you track the performance of each supplier over time,. This allowings you to spot patterns and know which suppliers to rely on for important orders.

For example, you might track component lead times from overseas suppliers. One supplier might consistently deliver in 14 days, while another often takes over a month.

Create custom fields in your supplier records to track key sales metrics, such as average delivery time and quality rating. Update these fields after each order to clearly see each supplier’s reliability.

Use Pipedrive’s Activities feature to monitor delivery schedules. When you order, create an activity for the expected delivery date. Set a reminder to check on the order if the due date approaches.

You can also record delivery delays or issues by using notes within activities or the supplier’s profile.

Use the data you collect in Pipedrive to identify your most reliable suppliers. Over time, these insights help you strengthen your supply chain with dependable partnerships.

4. Use sales pipeline data to forecast inventory needs

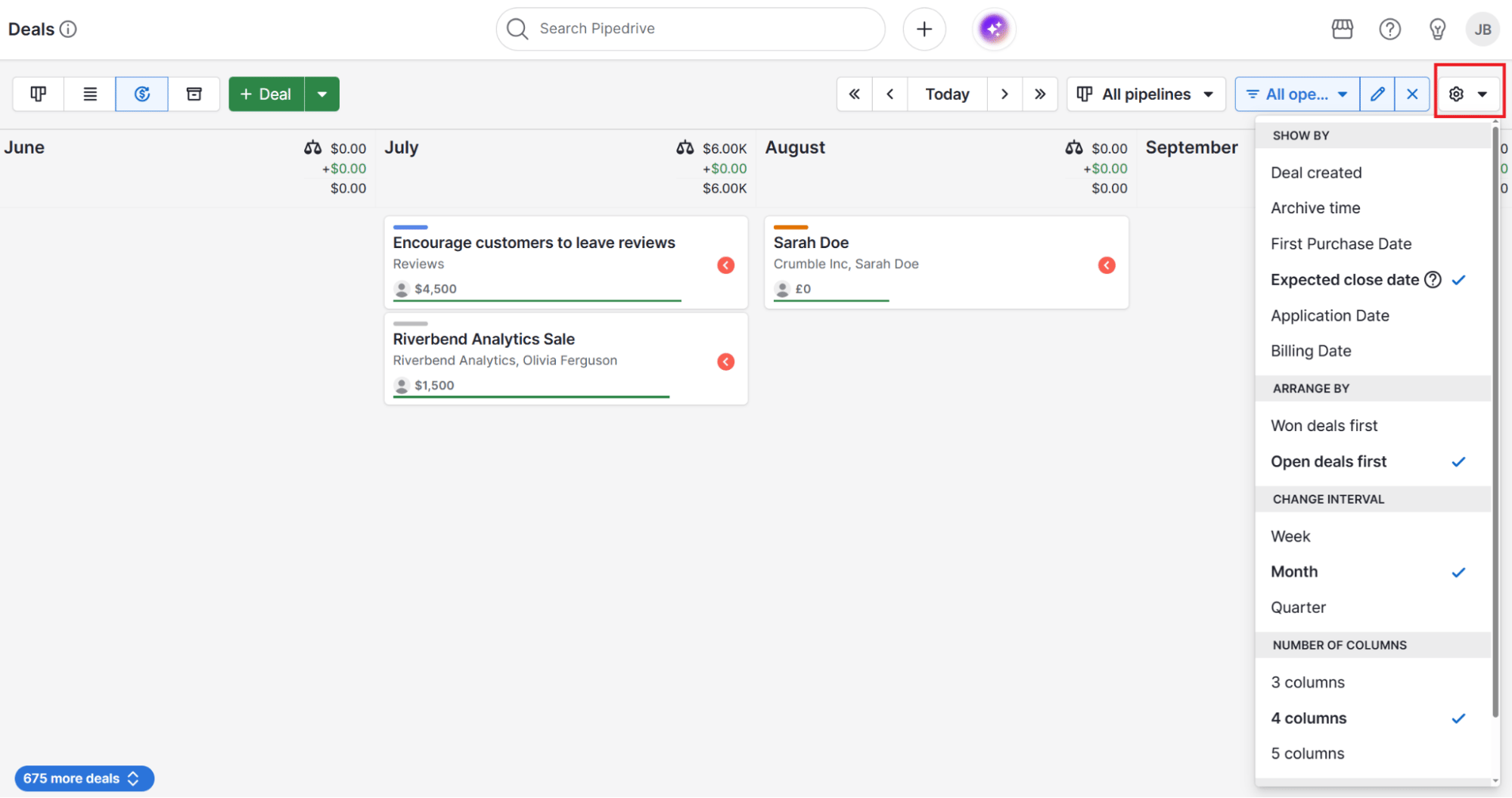

You can use insights from the sales pipeline you build to make data-driven decisions about ordering.

If your sales forecasting software predicts more demand for an item, you’ll know to place a larger order with your supplier. If forecasts show a drop in sales for another product, you can reduce orders to avoid overstocking.

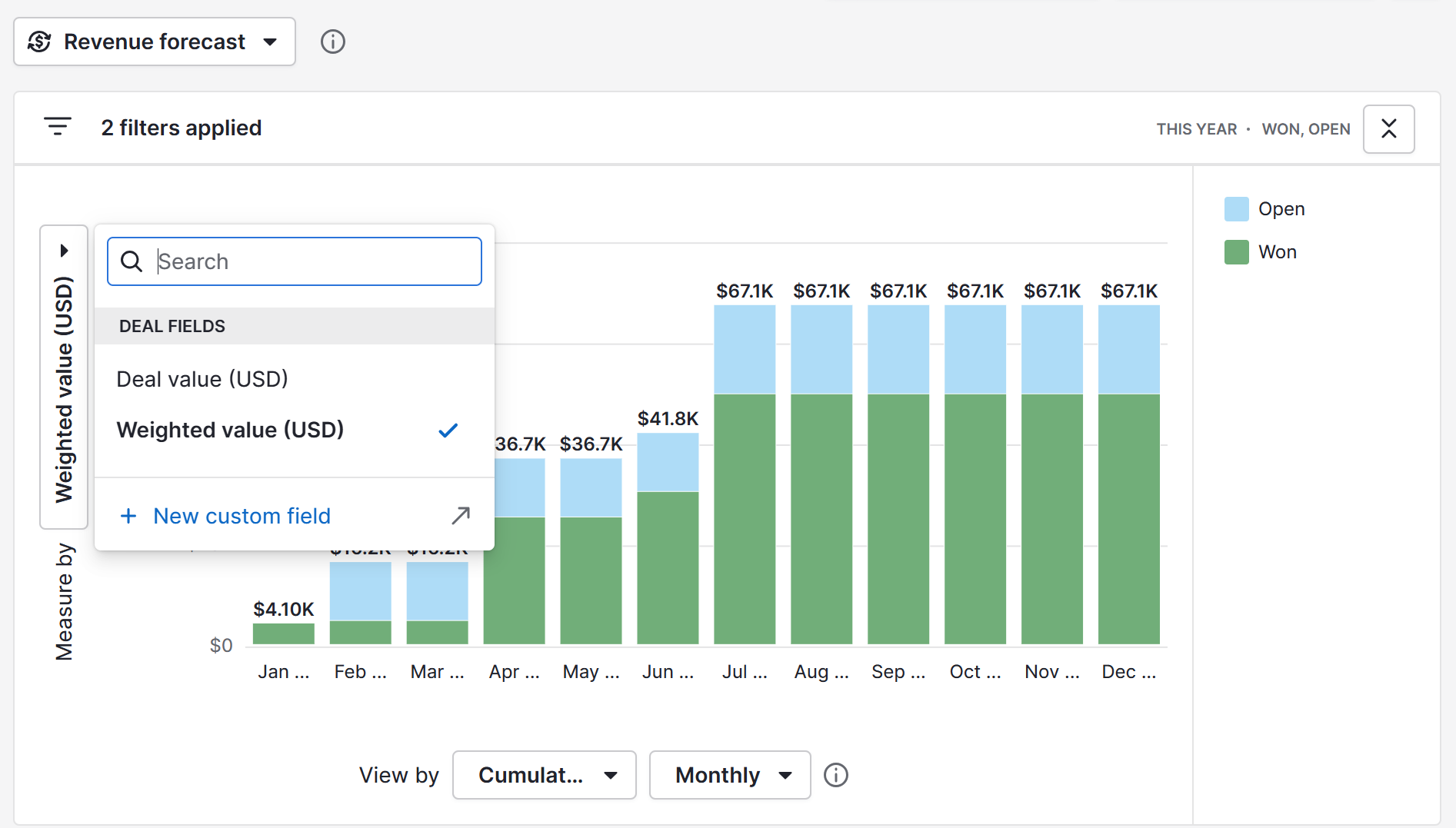

Pipedrive’s pipeline view shows you all your active sales deals and their expected close dates. Use this data to predict what finished products and raw materials you need and when.

Look at deals in your later stages. These deals will likely close, so you should prepare inventory for them. Seeing many deals in the last stages for a specific product is a good sign that you’ll need more soon.

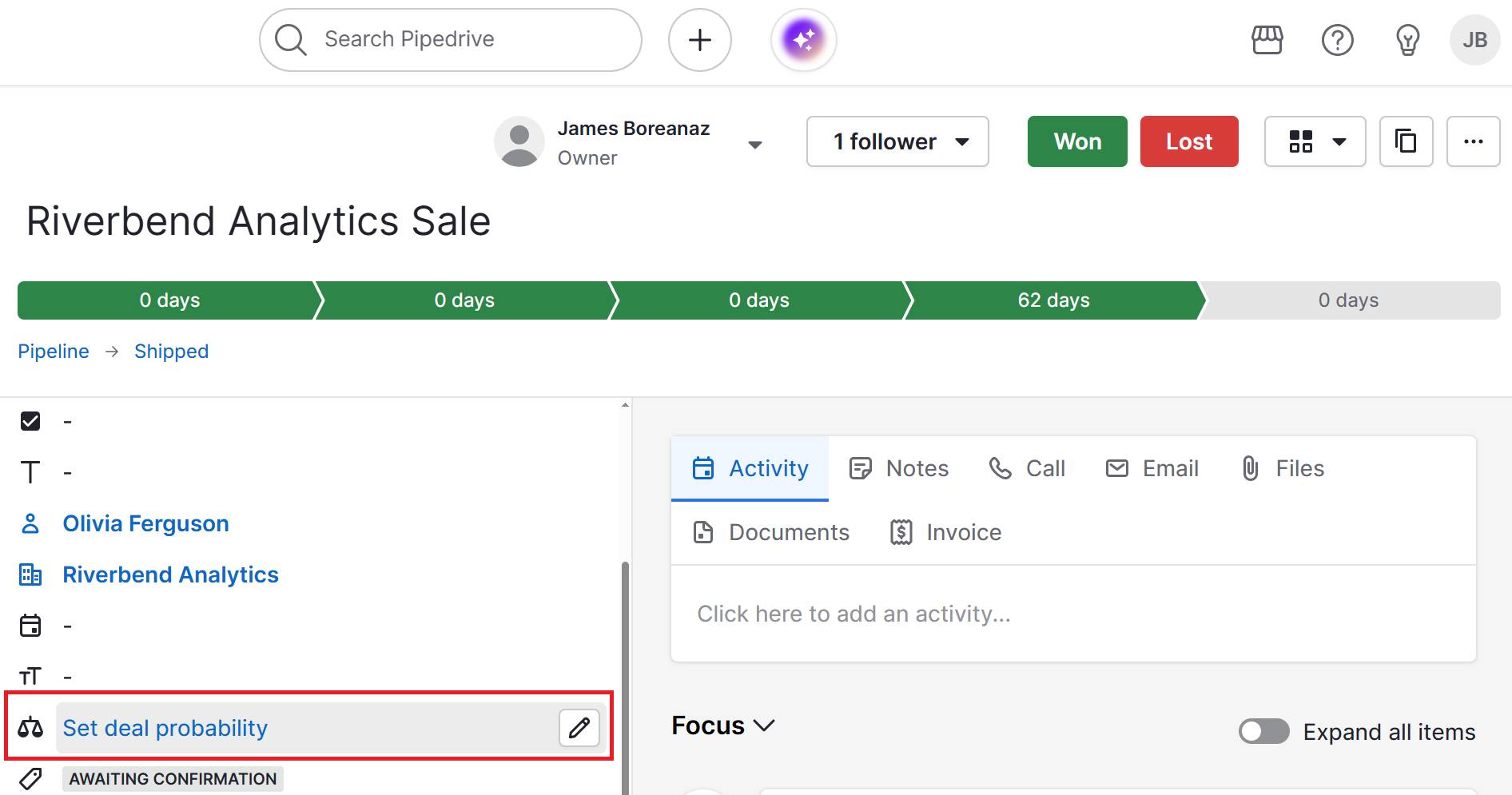

Set up weighted forecasts using Pipedrive’s deal probability settings. Press “Set deal probability” and add one to each pipeline stage.

Start with something like 25% for “Initial contact”, 50% for “Proposal sent” and 75% for “Negotiation”.

Then, create a report for “Deal weighted value” to get a forecast that considers these probabilities.

This approach helps you avoid running out of popular items, which can lead to lost sales and unhappy customers. It also enables you to avoid having too much stock, which can tie up your cash and take up valuable storage space.

5. Set automated follow-ups for supplier contract renewals

Missing a renewal can mean higher prices or a break in your supply. Pipedrive helps you automate reminders so you never miss a critical date.

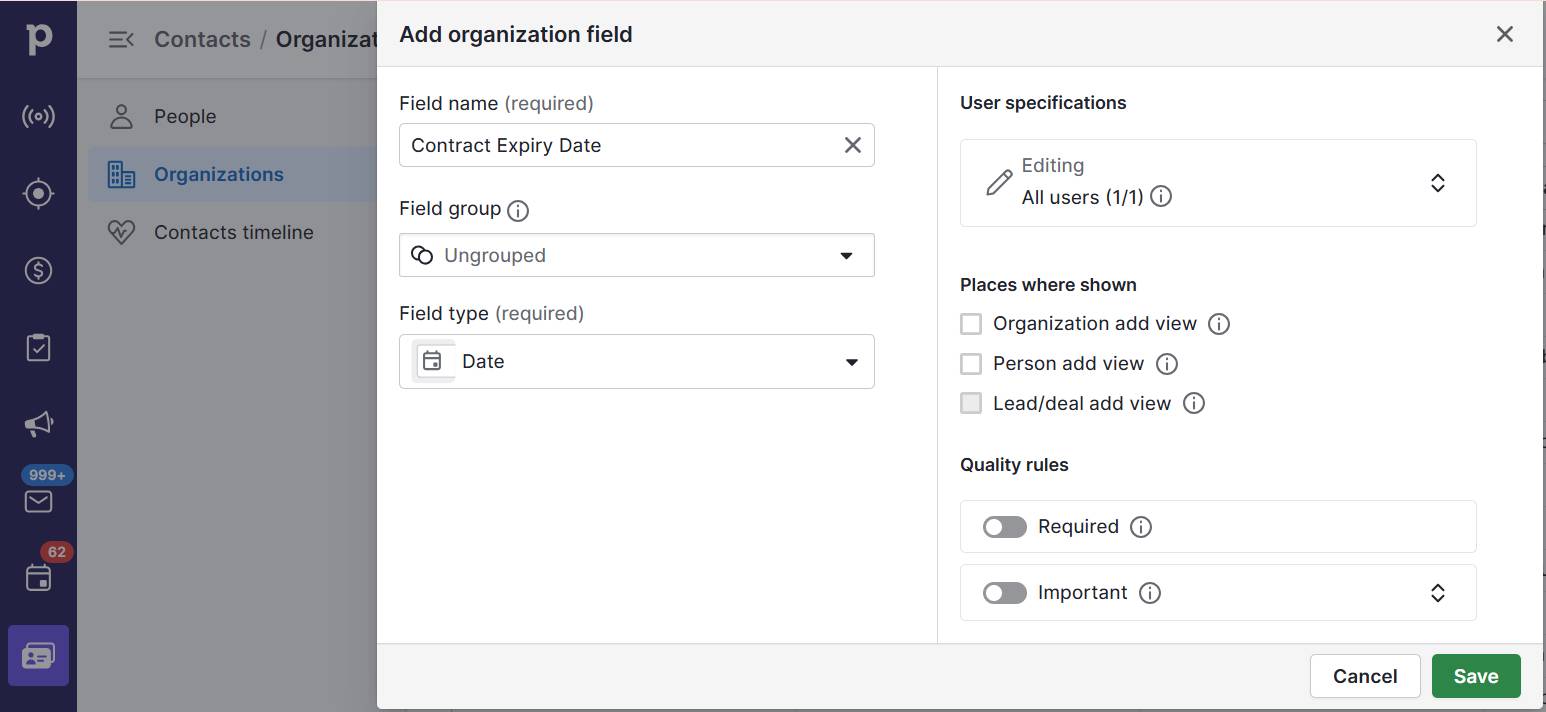

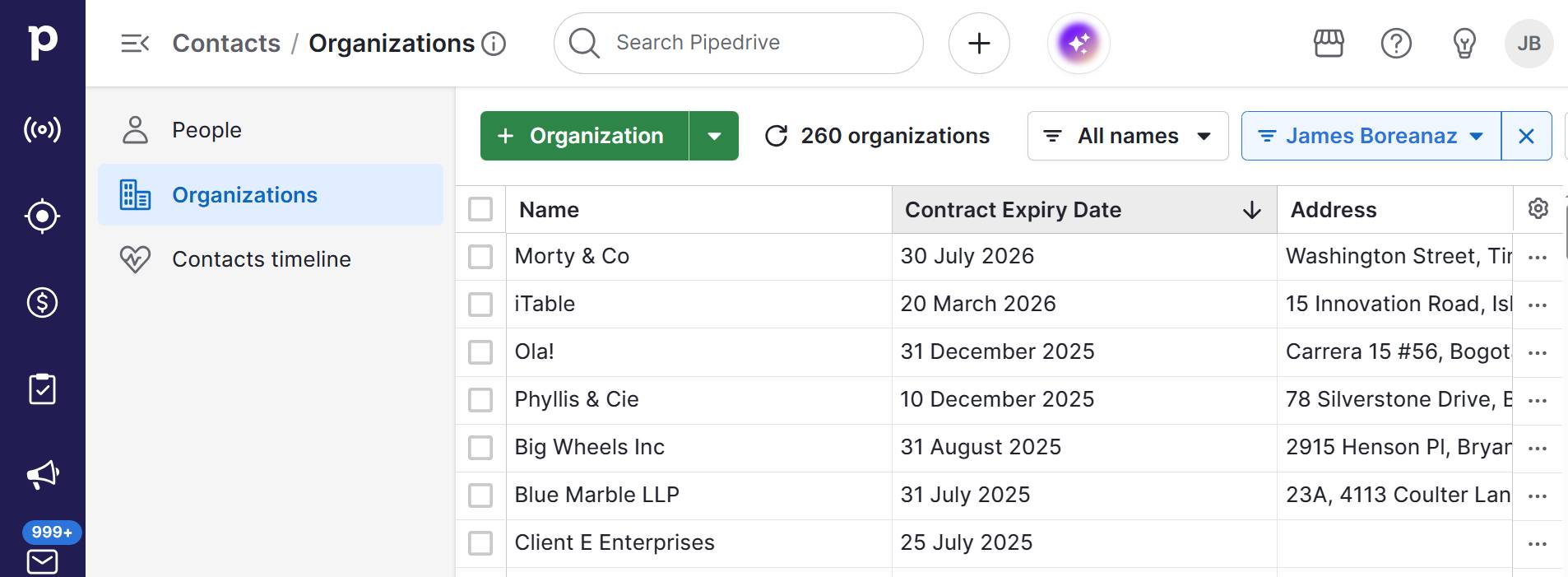

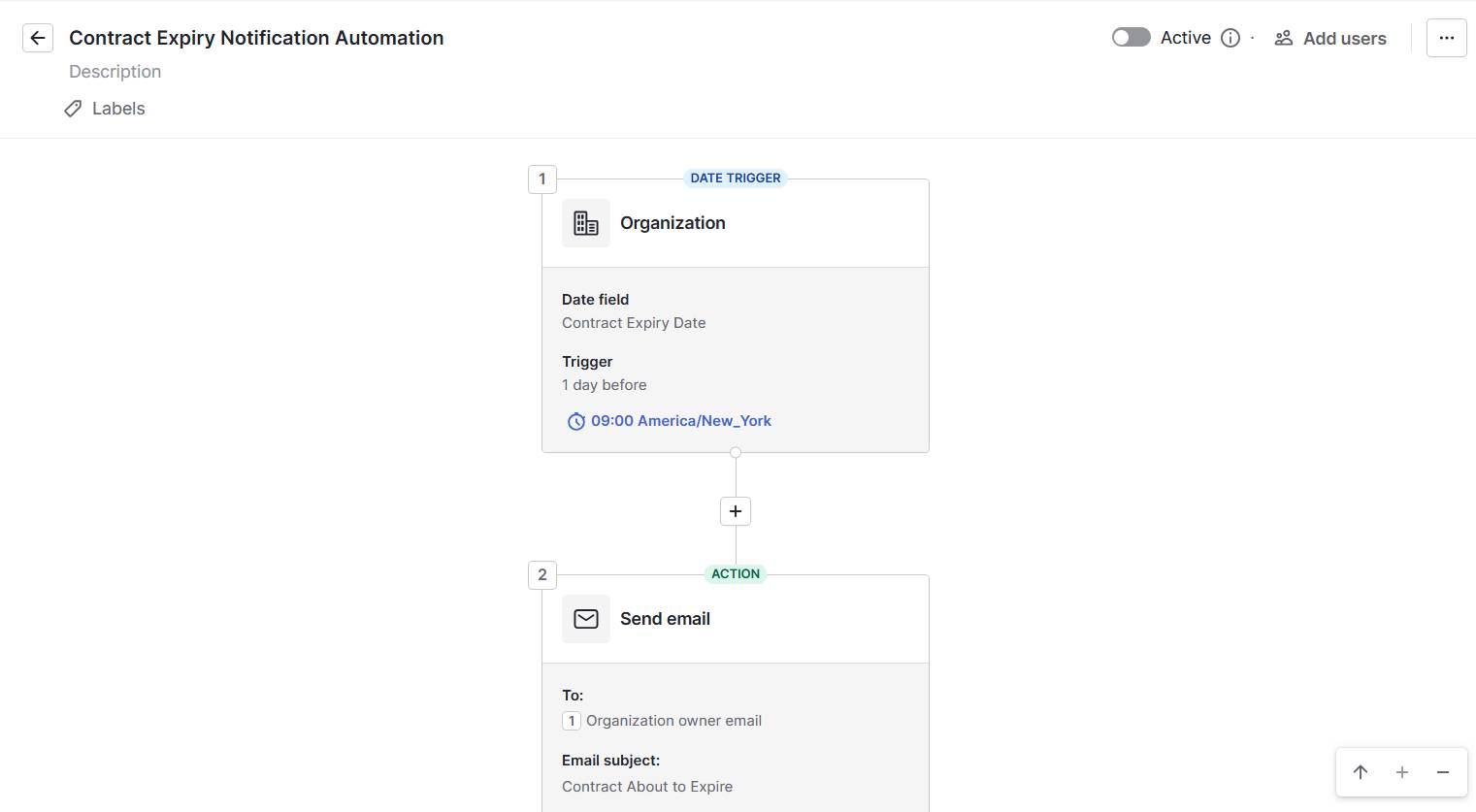

First, you need to track the contract end date for each supplier. In Pipedrive, go to your supplier’s organization record. Create a custom field called “Contract expiry date” and enter the date their agreement ends.

Once you’ve added the custom field, you’ll see it in each organization’s profile. Manually enter the contract end date for each supplier. You can also use filters to find suppliers with contracts ending soon.

Finally, use Pipedrive’s workflow automation builder to get a notification via email one day before the contract expiry date.

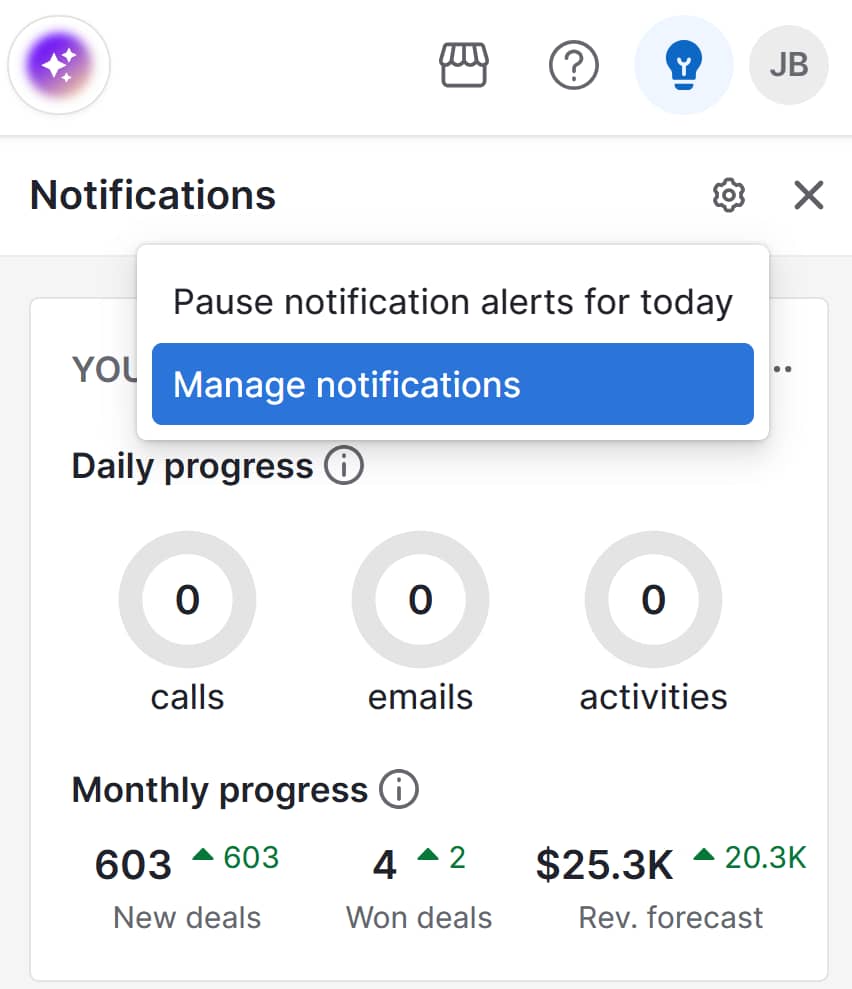

To set Pipedrive up so you get notifications when activities are due, press the light bulb icon, then gear icon and choose “Manage notifications”.

You can also use Pipedrive’s Activity Calendar for contract reviews. If your contract expires in December, schedule activities for October to start renewal discussions early.

For essential contracts, set multiple reminders. Create one activity 90 days before expiry to start discussions. Add another reminder at the 60–day mark for formal negotiations and a final one at 30 days to finalize terms.

Pipedrive’s reminders ensure you have plenty of time to review the contract, negotiate better terms or explore other suppliers. This feature helps you maintain favorable terms and avoid disruptions.

6. Track inventory levels and product information

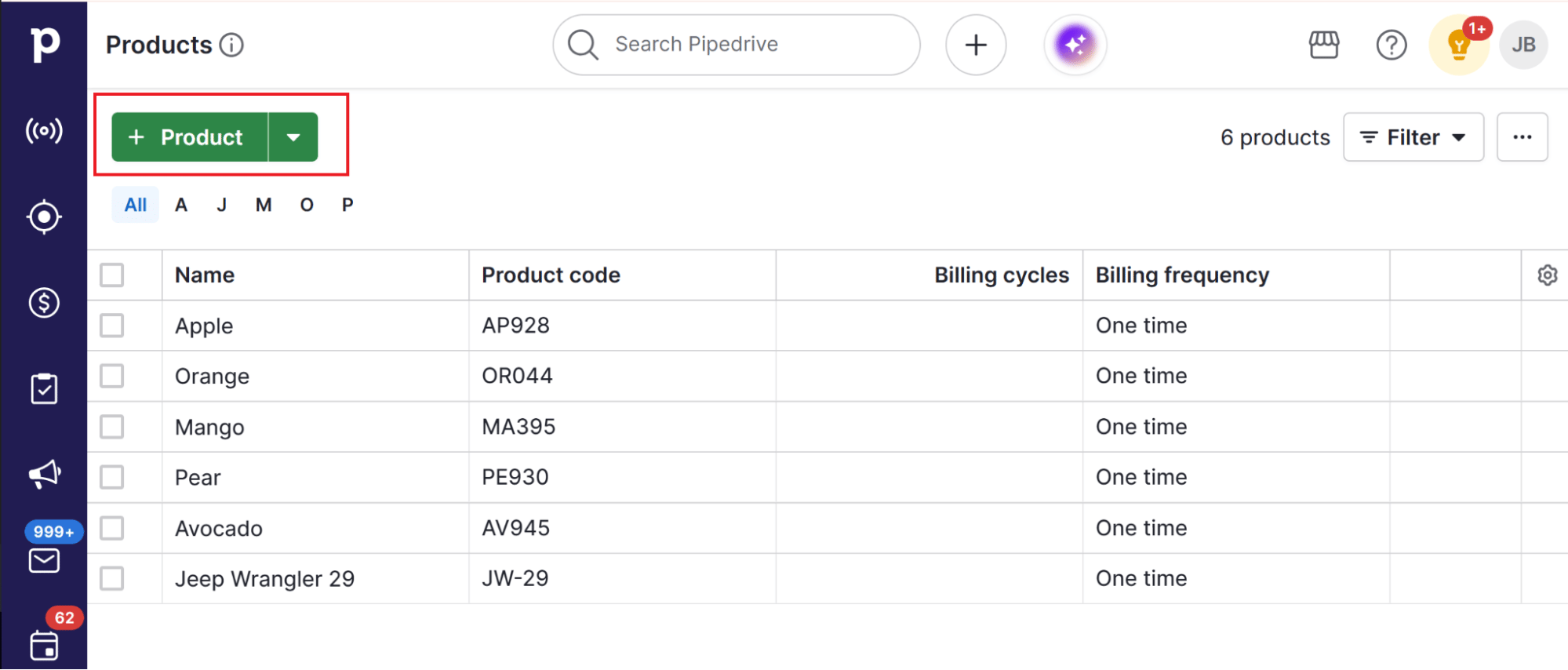

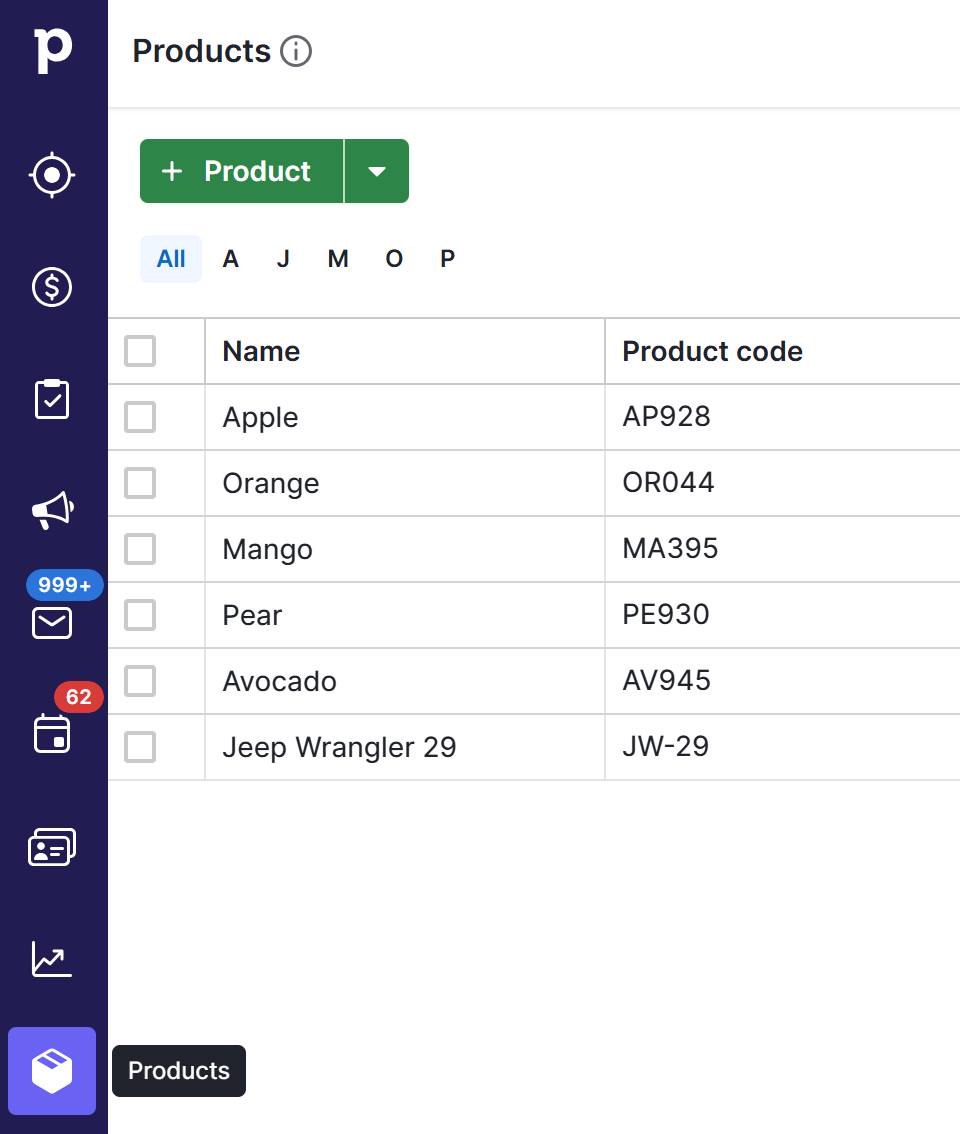

While Pipedrive isn’t a full inventory system, its Products feature allows you to track stock and product details.

To use this functionality for product management, go to “Tools and apps” > “Products”.

Once enabled, select the “Products” icon on the main navigation bar. Press “+ Product” to add a new product, then include all the necessary details.

Add custom categories for unique information that you want to store. Consider details that help your team handle the product, such as dimensions, weight or special instructions.

A useful field to add is “minimum reorder quantity”, which tells you how much stock you need before ordering more. You might also add “supplier SKU” to match the product code.

These custom fields help find crucial product information. Your sales team will know if an item is in stock before promising a delivery, and your operations team will also have all the information they need for packing and shipping.

7. Integrate with inventory management and e-commerce platforms

While its main strength is managing your sales pipeline, Pipedrive becomes even more powerful when you connect it with your other business systems.

The platform offers built-in integrations with relevant tools on the application Marketplace.

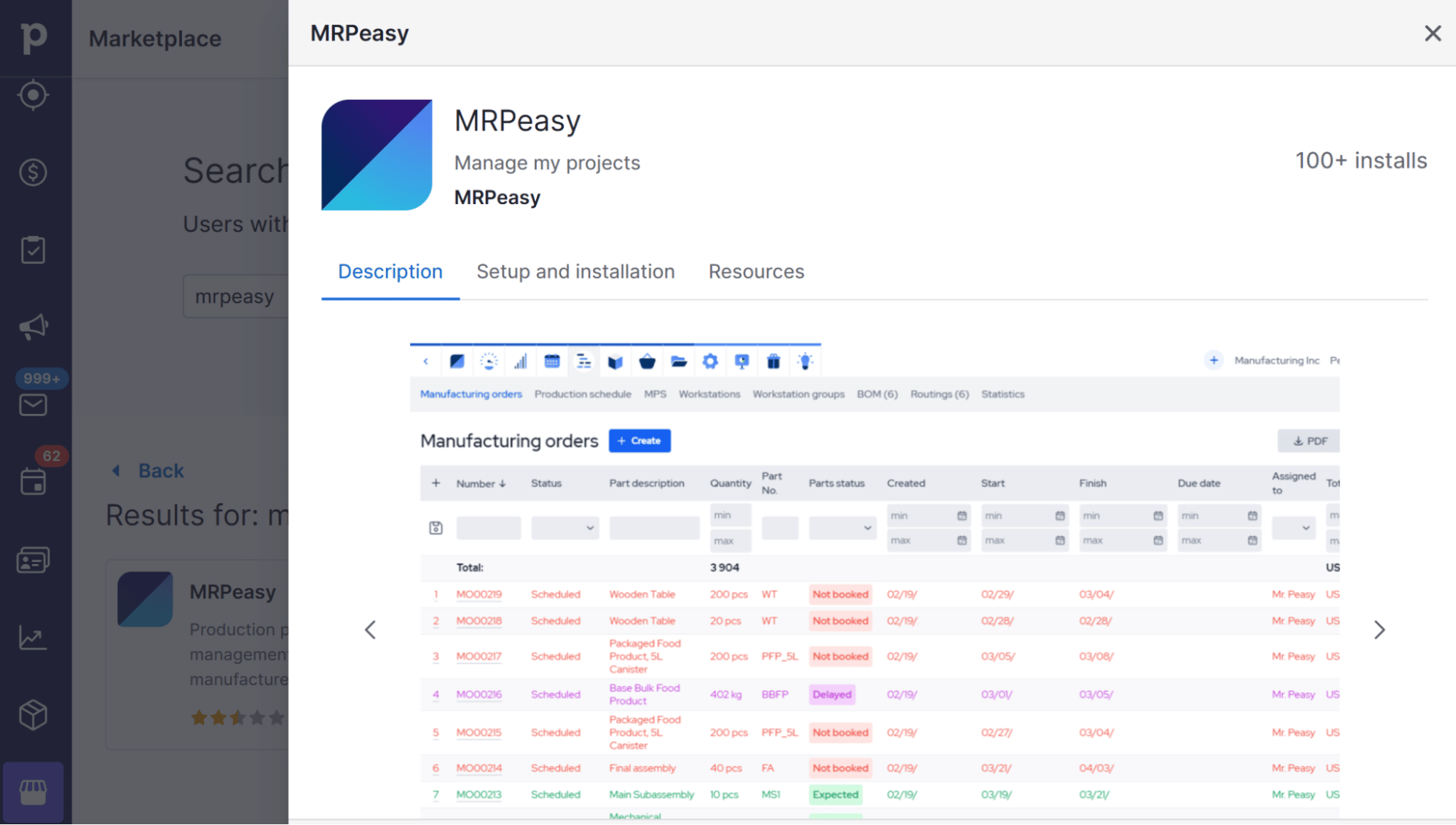

For example, it connects directly with MRPeasy, a cloud-based enterprise resource planning (ERP) solution that helps small manufacturers control production and scheduling.

You can also connect Pipedrive with e-commerce platforms like Shopify and WooCommerce.

When a new order comes in from an online sale, Pipedrive creates a new deal. It pushes customer and order details into your pipeline, helping your team see new sales and follow up with customers.

For many small businesses, Zapier is also an effective way to connect Pipedrive to other tools. It acts like a digital bridge, letting different apps “talk” to each other without coding.

Set up workflows (called Zaps) between Pipedrive and your inventory system. When you mark a deal “Won” in Pipedrive, a Zap can automatically trigger an action in an inventory management system like MRPeasy.

Note: Pipedrive offers a powerful Application Programming Interface (API) for businesses with specific needs. If you work with a developer, you can build custom connections between Pipedrive and nearly any other software.

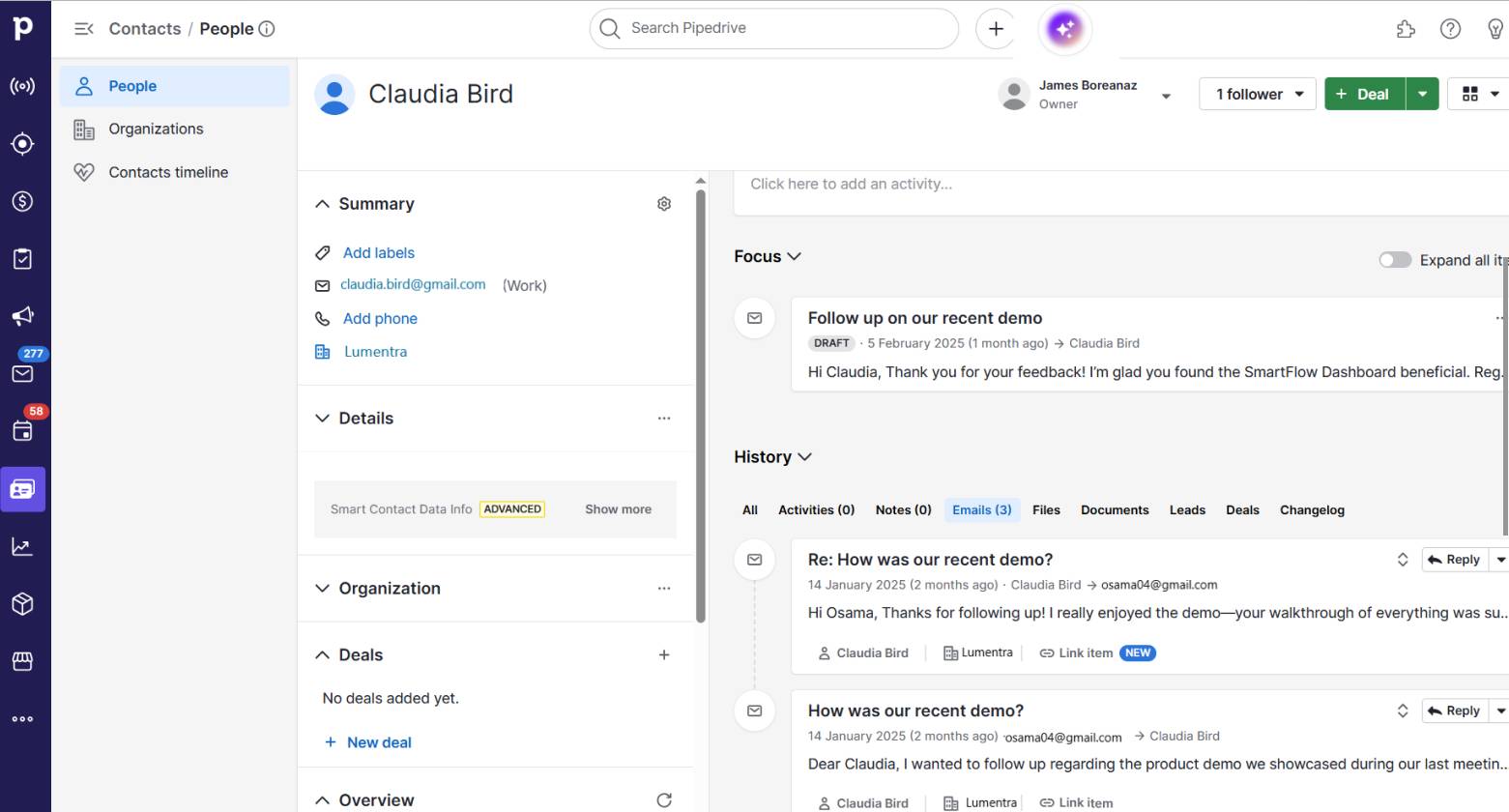

8. Generate reports on customer demand patterns

Effective supply chain management depends on understanding what customers want and when they want it. With Pipedrive, you can spot customer behavior trends and optimize procurement.

Pipedrive offers robust reporting capabilities to understand customer purchasing habits. The Insights feature lets you create custom reports that show you how customers are buying. Pipedrive’s AI report generator can produce any desired report using a written prompt.

Click on the “Insights” tab in Pipedrive’s sidebar to build reports and see which products sell the most over a specific period.

These reports reveal customer demand patterns. You might discover that certain items sell better in summer, or that a particular product is popular with customers in a specific region.

This information is crucial for your supply chain because it helps you:

Plan purchases more accurately. If a report shows a product’s demand doubles in October, order extra stock in September.

Optimize production schedules. Manufacturers use this data to ramp up production of high-demand items at the right time.

Improve product development. Seeing what customers are buying guides decisions about new products to offer.

Regularly checking these reports helps you align your supply chain activities with what your customers are asking for. You’re more likely to have the right products available at the right time, improving customer satisfaction.

5 best practices for managing small business supply chains

Getting started with supply chain CRM can feel overwhelming, but you don’t need to do everything simultaneously.

Focus on the basics first, then build from there as your team gets comfortable with the system:

Start with critical suppliers. Focus early efforts on the vendors you deal with the most. Experiment with your CRM’s tools and develop a manageable supply process before expanding to every supplier.

Set up key performance indicators (KPIs). Define clear supply chain goals, such as on-time delivery percentage (aim for 95%+) and average order fulfillment time (target under 48 hours). Check these numbers often to see what’s working and what needs improvement.

Train your team. Make sure everyone who needs to use your CRM knows how. Provide CRM onboarding for your sales team, operations staff and anyone involved in purchasing. Document each process so your staff uses the system more effectively.

Prioritize data quality and audits. A CRM is only as good as the data in it. Regularly review your supplier and product portfolio. Update outdated information (like old contact details) and create a consistent process for how your team enters data.

Gather customer feedback. Use your CRM to track feedback on product quality and customer experiences. Look for everyday customer needs (like faster delivery options) to boost customer loyalty and attract new customers.

As your needs evolve, remember that your supply chain is constantly changing. Regularly review your data, reports and workflows. Are your forecasts still accurate? Are your automated reminders effective? Is supplier performance improving or declining?

Be prepared to adjust your business processes and even your supplier relationships based on the insights you gain.

Final thoughts

Using CRM for supply chain management helps small businesses avoid stockouts and strengthen supplier relationships.

Start with the customer data you already have. Over time, you’ll see improvements in inventory, ordering and deliveries.

Try Pipedrive free for 14 days and see how much easier it is to manage suppliers, predict what you need to order and keep customers happy.